- saffronmachinery@gmail.com

- +91-70165 35087

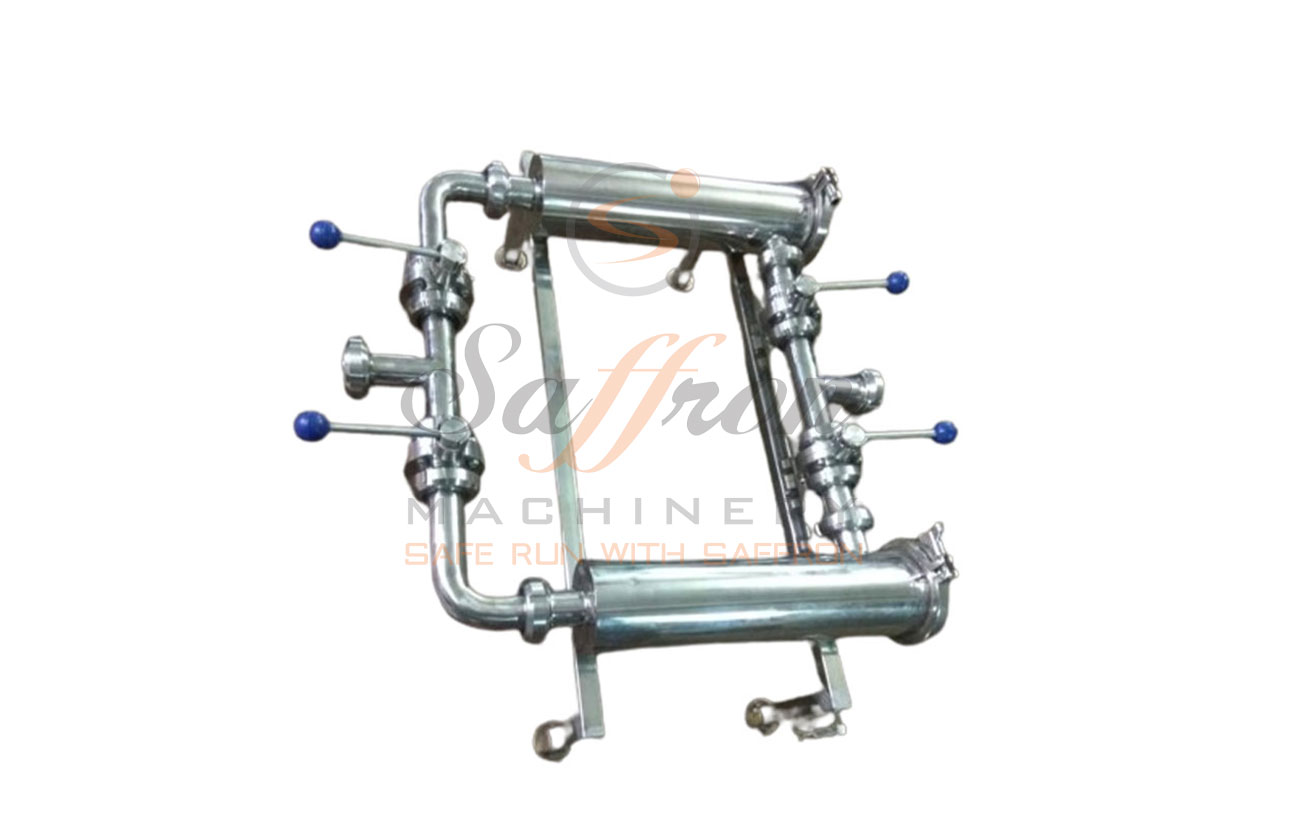

Milk Filter

Milk Filter

A milk filter is an essential component in the dairy industry, particularly in the process of raw milk filtration before further processing. The primary purpose of a milk filter is to remove impurities, such as dirt, hair, debris, and somatic cells, from the raw milk.

Here's how a milk filter typically works:

Filtration Medium: Milk filters are usually made of porous materials like paper, cloth, or synthetic fibers. These materials allow milk to pass through while trapping larger particles and impurities.

Installation: Milk filters are installed in-line between the milk collection point (such as a milking machine or a dump tank) and the storage or processing equipment. They can be placed within a filter holder or filter housing designed for easy installation and replacement.

Filtration Process: As raw milk flows through the filter, the porous material traps any solid particles or contaminants present in the milk. This process ensures that the milk reaching the storage or processing equipment is clean and free from foreign matter that could affect the quality and safety of dairy products.

Maintenance: Milk filters need regular inspection and replacement to maintain their effectiveness. Depending on the level of impurities in the milk and the type of filter used, they may need to be replaced after each milking session or after processing a certain volume of milk.

Using milk filters is critical for maintaining the quality and safety of dairy products. They help prevent contamination, improve product consistency, and ensure compliance with regulatory standards for milk quality.

Overall, milk filters are an integral part of the dairy processing workflow, helping to remove impurities and maintain the purity of raw milk as it moves through the production process.